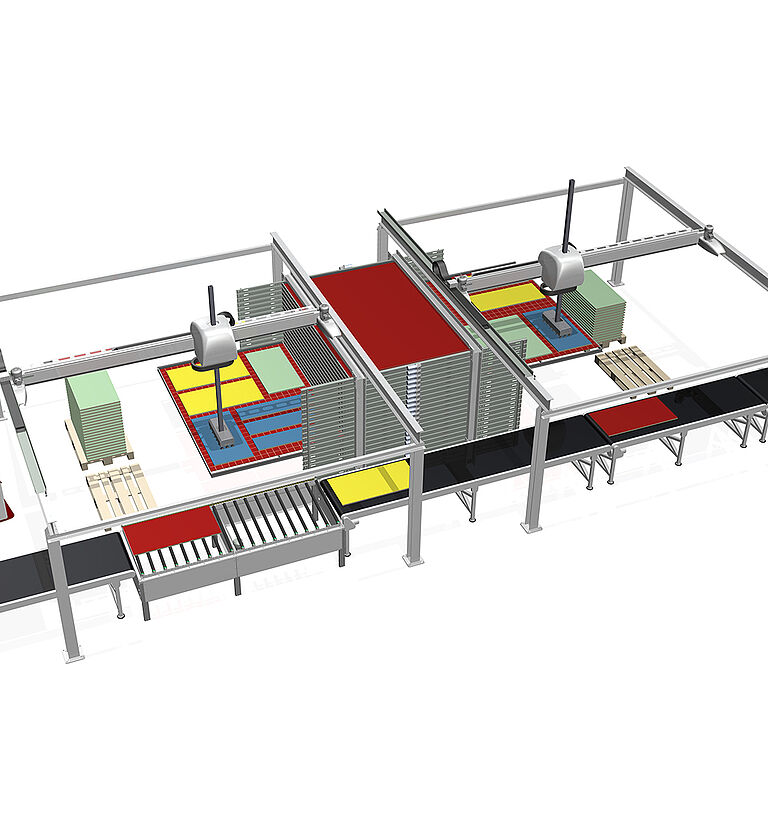

PBX Buffer Storage

Newest development of Barbaric. Buffering of parts in furniture manufacturing. The buffer storage PBX assures a constant flow of parts in the production. In order to cushion different processing times of individual machines, the interim storage of parts is indispensable for a modern production line.

Designs

- One-sided version with a single XYZ manipulator

- Two-sided design with two XYZ manipulators

- Versions with various conveyor systems in the surrounding area of the buffer

Technical data

- approx. 120 m² storage area in a small space

- cycle times of up to 6 parts/min.

- max. panel size 2,8 x 1,95 m

- max. panel thickness 25 mm, optional: 40 mm

- individual designs possible

- Each drawer is individually driven, enabling overlapping opening and closing processes

Technical changes and errors excepted.

Advantages at a glance

- Flexibility of production

- Individual and instantaneous access to all parts at all times

- Increase of productivity

- Optimization of personnel costs

- Continuous material flow at the edge bander

- Grouping of parts for individual orders

- Cushioning of different processing times on individual machines

- Unbundling of production

- Safety buffer in case of machine failures

- Parts tracking and visualization

Case studies

Ideas that move!

Learn more about our realized customer projects.

Our sales team is there for you!

If you have any questions or would like a quote, please contact us.

Phone: +43 732 779800

Email: sales-automatic@barbaric.at

After-Sales-Service

We are there for you - even years after the sale.

In order to ensure that our handling systems function optimally, we rely on good cooperation with our customers and particularly customer-oriented support through our competent service team.

Our products

Manual vacuum lifters from Barbaric enable efficient handling of heavy wood and glass panels and save valuable time in production. While conventional manipulation by hand requires 2-3 employees, a vacuum lifting systems allows a single employee to move oversized panels with maximum ergonomics and without physical exertion.

Product overview Manual lifters

Our automatic handling solutions take over fully automated process steps in wood panel and part production. Panel storage and retrieval systems, feeding systems, buffer storage and return systems are just a few examples of modern systems in the field of material handling. All of our machines are built individually according to the requirements of our customers, while proven handling concepts and trusted components are used.