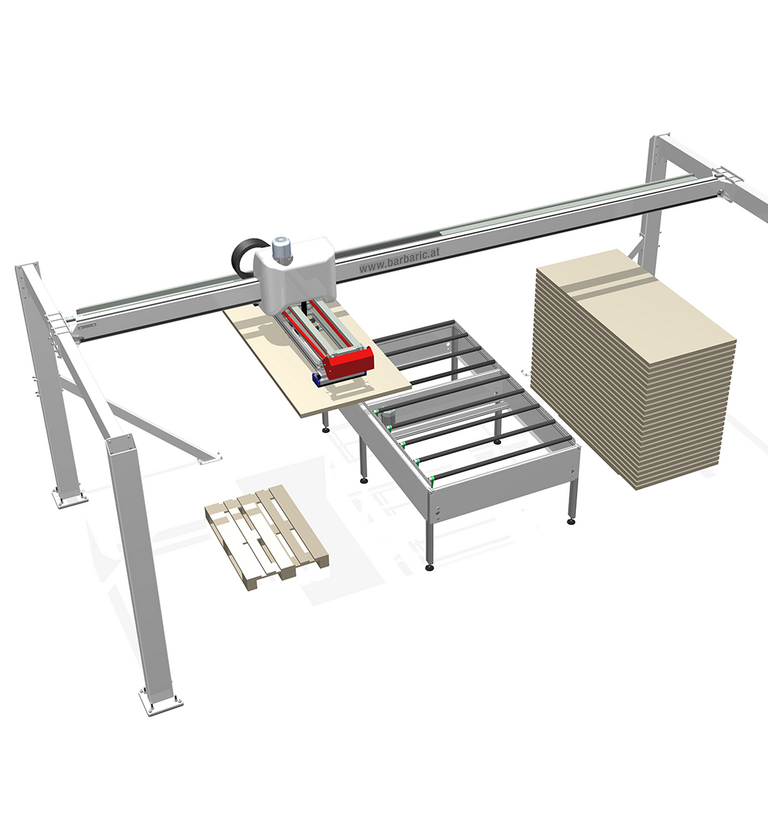

Door manipulator TMP

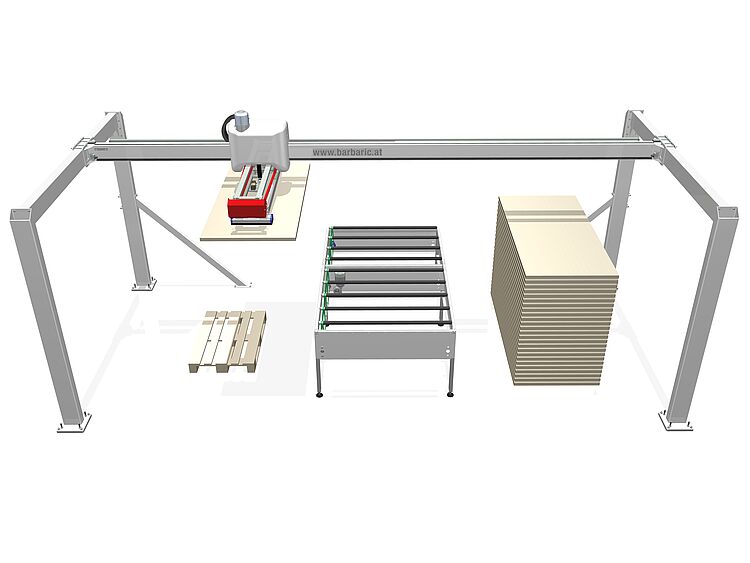

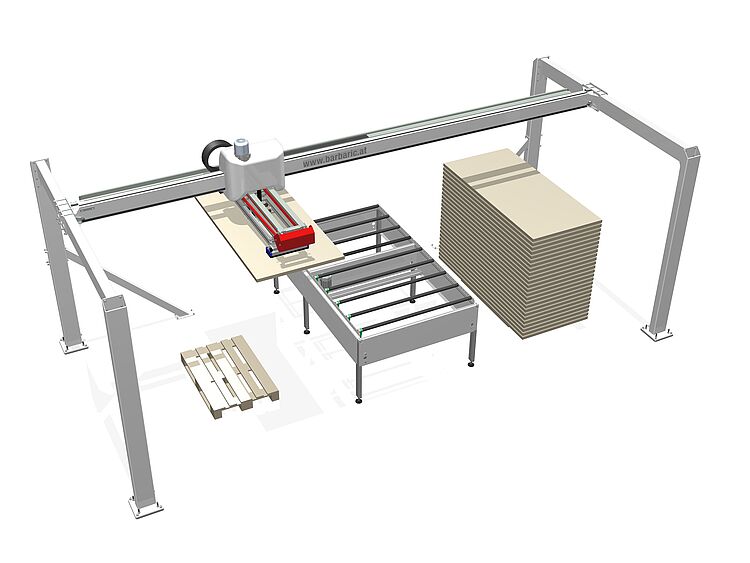

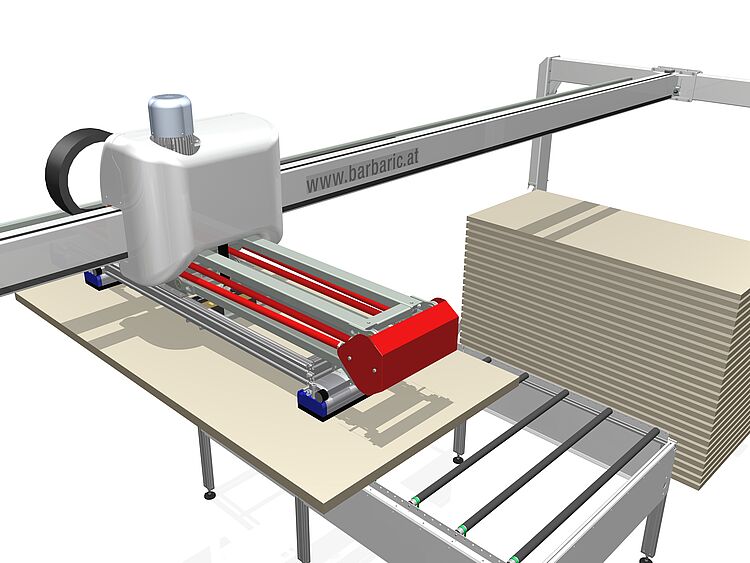

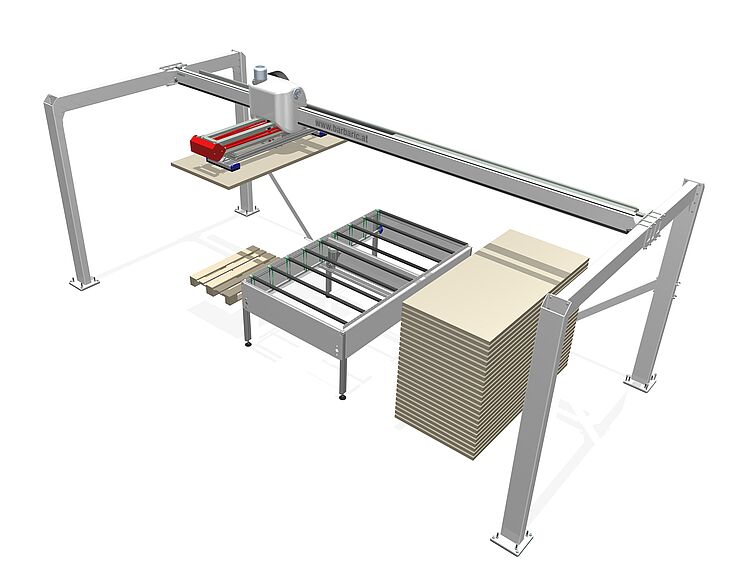

Optimized production processes, increased productivity and relief of employees. Fast and compact systems in an appealing design for loading a CNC with subsequent stacking of doors.

Optimized production processes in the door manufacturing

With the door manipulator TMP company Barbaric sets new standards in terms of optimized production processes in the door manufacturing. The system has a very slim and compact design that allows for a very quick manipulation of boards and extremely low cycle times. Also, roller conveyors or barcode scanning stations can be integrated into the automatic system.

All advantages at a glance

The application area is for example the automatic feeding of a CNC, subsequent stacking of machined doors or other stacking processes.

Case studies

Ideas that move!

Learn more about our realized customer projects.

Our sales team is there for you!

If you have any questions or would like a quote, please contact us.

Phone: +43 732 779800

Email: sales-automatic@barbaric.at

After-Sales-Service

We are there for you - even years after the sale.

In order to ensure that our handling systems function optimally, we rely on good cooperation with our customers and particularly customer-oriented support through our competent service team.

Our products

Manual vacuum lifters from Barbaric enable efficient handling of heavy wood and glass panels and save valuable time in production. While conventional manipulation by hand requires 2-3 employees, a vacuum lifting systems allows a single employee to move oversized panels with maximum ergonomics and without physical exertion.

Product overview Manual lifters

Our automatic handling solutions take over fully automated process steps in wood panel and part production. Panel storage and retrieval systems, feeding systems, buffer storage and return systems are just a few examples of modern systems in the field of material handling. All of our machines are built individually according to the requirements of our customers, while proven handling concepts and trusted components are used.