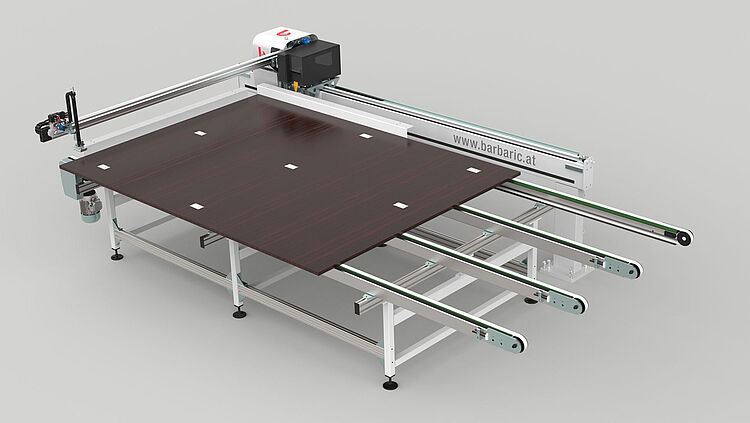

Labeling Printer LPS

The Labeling Printer LPS perfectly completes Barbaric's range of products in the field of panel handling and offers an optimal extension of our storage or feeding systems for part cutting. With this unit, boards can be labelled even before they are cut to size. Manual labelling after cutting and problems with part identification are now a thing of the past.

Features

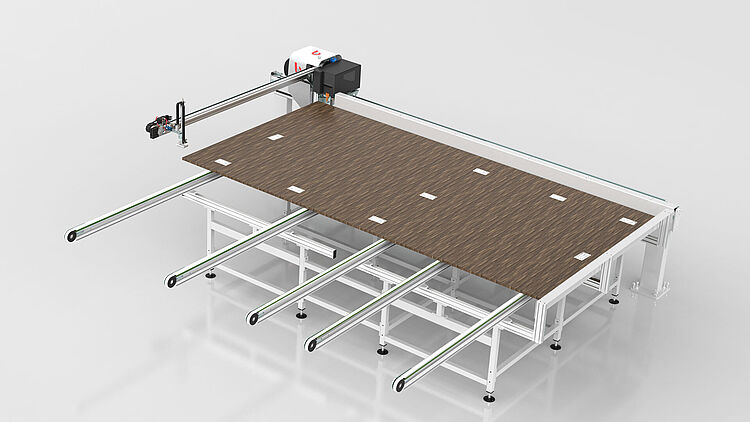

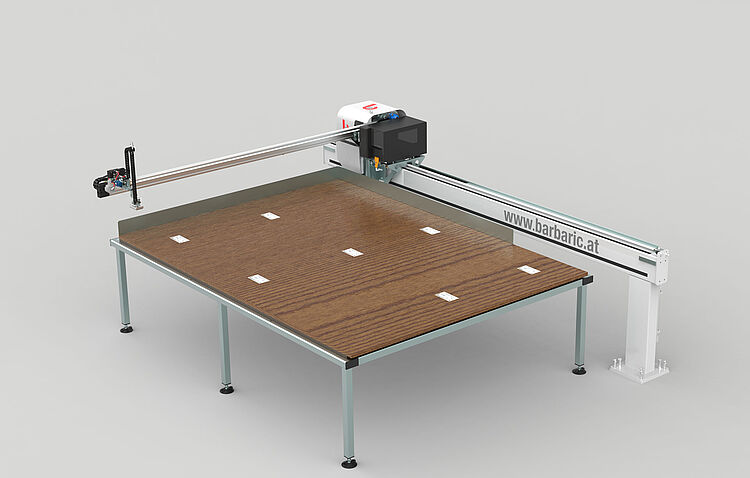

The Labeling Printer LPS can be implemented in a wide variety of set-up variants: as a stand-alone printer in a panel storage system, behind a pressure beam saw with direct feeding by means of a toothed belt conveyor or in front of a nesting machine with the corresponding conveyor unit. The same printer or applicator unit is used for all variants, only the lengths of the axes are different.

The communication to higher-level controllers is very simple. The LPS label printer only requires the finished generated labels in JPG or BMP image format and a position file for each cutting plan. Thus the creation of the labels is purely on the side of the cutting plan or nesting optimization.

All benefits at a glance

- Fully automated labelling without operator intervention

- Human error when applying labels is eliminated

- Labelling before cutting or nesting

- Part identification with unique and unambiguous part number

- One printer for several processing machines (only for the standalone version)

- Effective and trouble-free cutting

- Alternatively also with manual labelling after cutting for small parts

- Standard label sizes but also customized labels can be used

Technical data

- Max. 10 cycles per minute

- Panel sizes from 2000 x 600 mm to max. 5600 x 2100 mm (depending on the model)

- Application accuracy up to +/- 1 mm

- Standard labels in 98 x 55 mm format

- 104 mm max. print width

- Axes controlled by frequency converter

- Standardized interface for cutting plan or nesting optimization

Other solutions

In addition to the standard LPS machine, Barbaric also offers other customized printer solutions:

- Manual labelling stations

- Stack labelling

- Continuous labellers

- Label stations with two printers for different label sizes (simultaneous application of large and small labels possible)

Technical changes and errors excepted.

Case studies

Ideas that move!

Learn more about our realized customer projects.

Our sales team is there for you!

If you have any questions or would like a quote, please contact us.

Phone: +43 732 779800

Email: sales-automatic@barbaric.at

After-Sales-Service

We are there for you - even years after the sale.

In order to ensure that our handling systems function optimally, we rely on good cooperation with our customers and particularly customer-oriented support through our competent service team.

Our products

Manual vacuum lifters from Barbaric enable efficient handling of heavy wood and glass panels and save valuable time in production. While conventional manipulation by hand requires 2-3 employees, a vacuum lifting systems allows a single employee to move oversized panels with maximum ergonomics and without physical exertion.

Product overview Manual lifters

Our automatic handling solutions take over fully automated process steps in wood panel and part production. Panel storage and retrieval systems, feeding systems, buffer storage and return systems are just a few examples of modern systems in the field of material handling. All of our machines are built individually according to the requirements of our customers, while proven handling concepts and trusted components are used.