Solid wood handling and Pre-fabricated house construction

The innovative handling solutions for solid wood in the timber industry and prefabricated house construction.

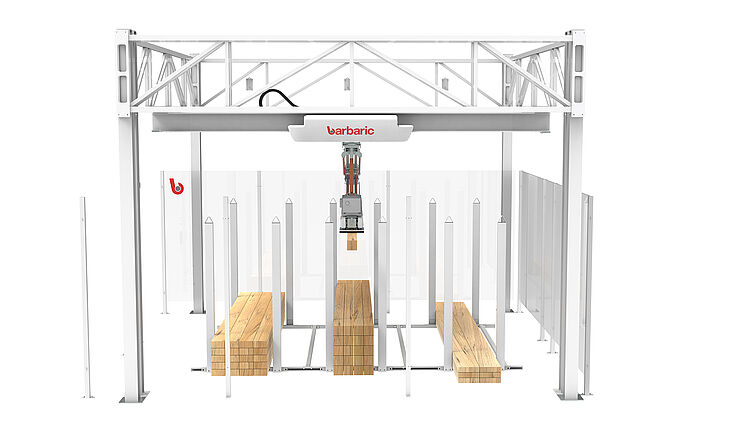

The system

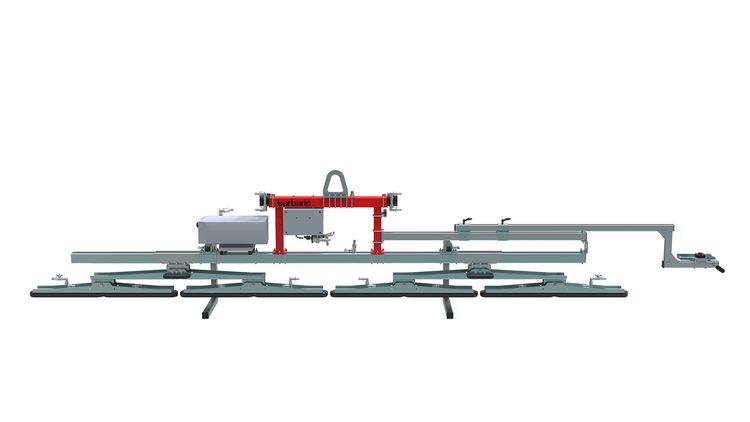

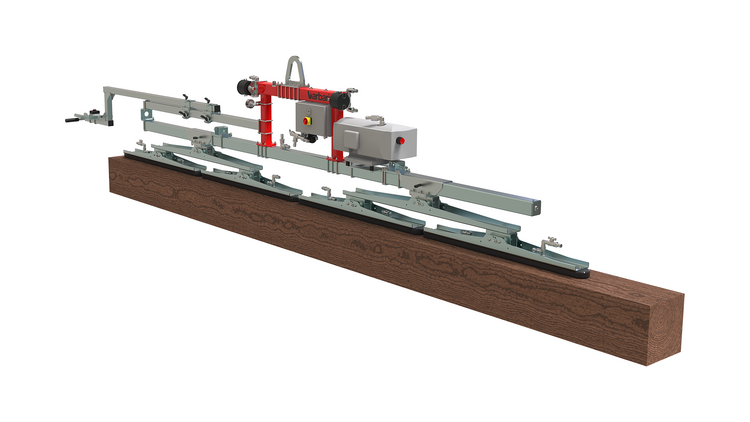

The SWS solid wood storage system is the optimal system for the storage of glulam and solid construction wood poles.

Solid wood logs are stored in stanchion compartments and can then be fed to cross-cut saws or joinery lines. Furthermore, there is the possibility of simple commissioning of customer packages or complex package formation after joinery.

These systems impress with their high flexibility. The stanchion compartments can easily be adapted to the desired log widths. Several logs can be stored in one layer per stanchion compartment. This significantly increases the performance of the system compared to conventional one-dimensional storage.

The integration of heavy conveyor technology is essential for this type of plant. Chain conveyors or roller conveyors can be easily integrated into the system.

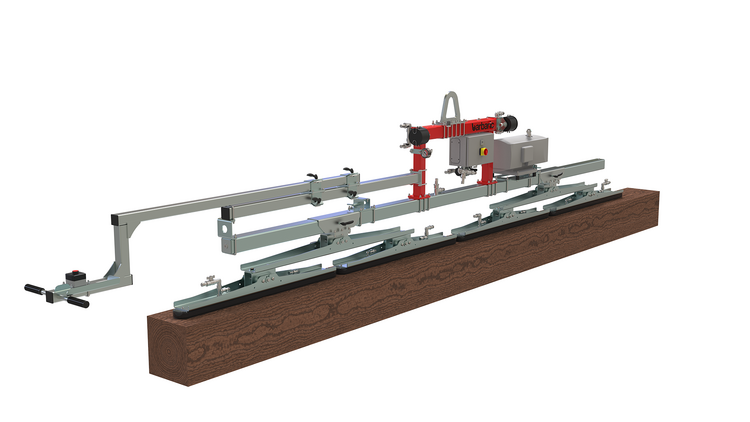

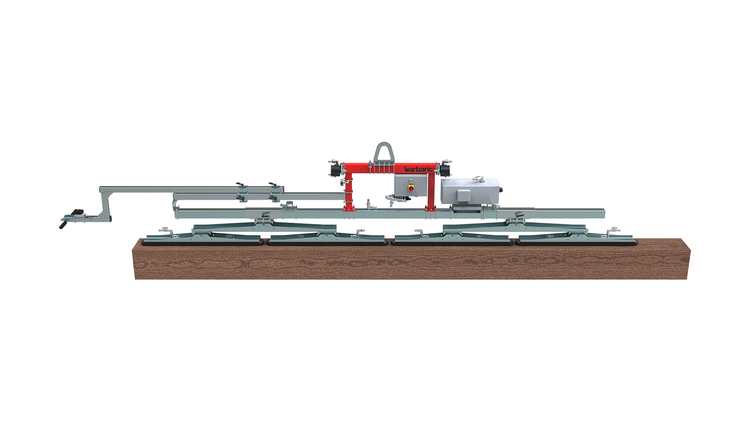

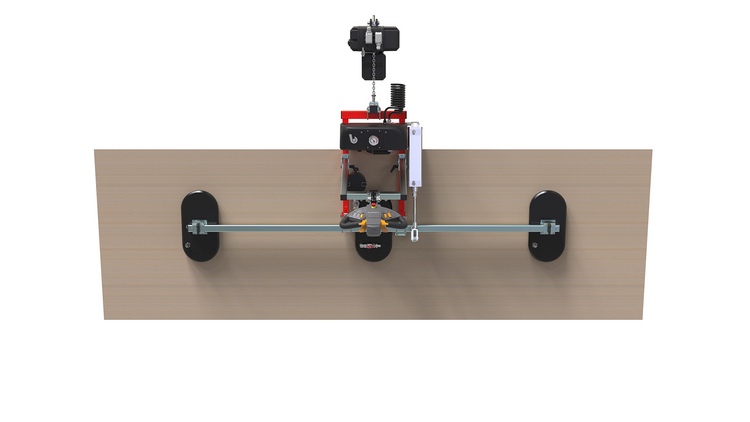

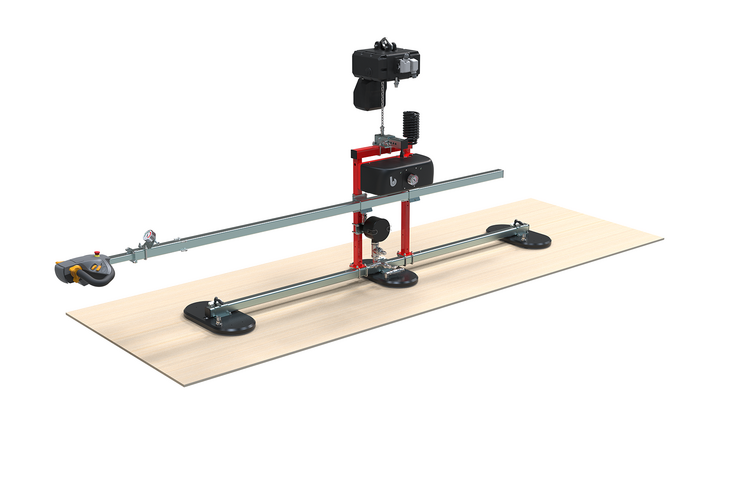

The suction beam

The suction traverse has been designed in such a way that several bars can be picked up at the same time. Depending on the dimensions of the individual bars, one bar or up to 5 bars can be suctioned at the same time.

The individual suction circuits are automatically controlled according to the requirements or the dimensions and number of bars. With only one stroke several bars can be transported and thus also a lot of energy is saved.

With this solution, the system achieves a significant increase in performance. Cracked bars can also be picked up and transported with the specially developed suction cups.

Technical details

| Load capacity: | 500 kg (optional 700 kg & 1000 kg) |

| Length min: | 1500 mm |

| Length max: | 16 m |

| Width min: | 80 mm |

| Width max: | 400 mm |

| Height min: | 40 mm |

| Height max. | 260 mm |

| Stacking height: | 1800 mm / 2500 mm or more |

| Multidimensional stacking |

Other dimensions possible after consultation and technical inspection.

Do you need more information or would you like a quote?

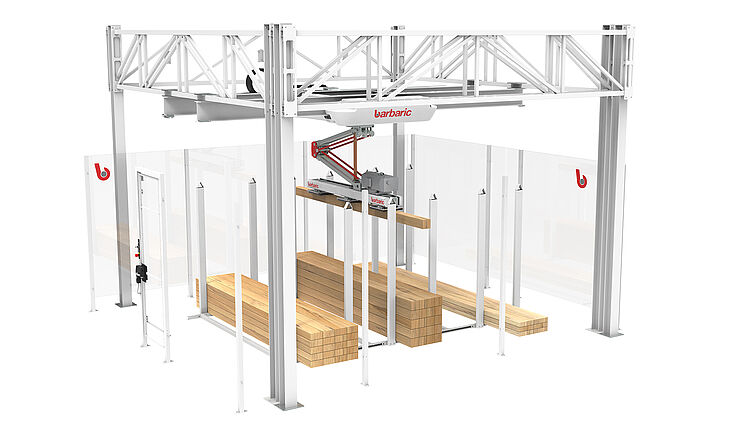

Simple or multi-level solutions

The solid wood storage system SWS can be realized as a floor storage system but also as a two-storey version. The standard solution is a warehouse on one level. Depending on the required performance of the system, one or two manipulators can be used.

The next step is a two-level facility. High hall heights are optimally used by adding an intermediate floor to the system and the resulting upper area can also be used for storage.

This area can be used mainly for B&C goods or also for residual bars. The lower stacking heights even allow storage without stanchions.

Interlinking with machines & ERP system

Depending on the desired application, a wide variety of machines can be linked. Whether simple cross-cut saws or complex joinery centers - everything is possible. Not only the feeding of the system, but also the further handling with finished individual parts is possible. Depending on the set-up, residual parts can also be stored again. The connection of the machines is realized via modern interfaces. The open interfaces can also be used by ERP systems. All storage and material data are available to other systems.

The green idea

This machine is not only a warehouse but also helps the environment with the chosen technology. The drive and vacuum technology was chosen so intelligently that the required electricity was reduced to a minimum. The vacuum is generated directly where it is needed. Any losses are avoided. The compact yet stable design allows the use of comparatively low drive power. By accommodating several bars, the number of travel movements is drastically reduced.

Press article about the SWS Solid Wood Storage

"Einlagerung und Selektion massiv beschleunigen" // Holz + Möbel 2020 - German only

An editorial article in the trade magazine Holz & Möbel 2020 about the realization of a solid wood warehouse at our customer Feil GmbH in Siegsdorf near Traunstein/Germany informs about the advantages of the solid wood warehouse and the facilitation of the pre-selection of workpieces for production.

In the store-in area, a laser scanner automatically detects the edges of the wooden planks and also saves an image of the wood grain. The storage software not only keeps track of the planks regarding formats and quantities, but also offers an overview of the workpiece surface before ordering planks for store-out or feeding into a machining centre.

With this solution we can offer a fully automated store-in of delivered wooden planks on a pallet. First a layer with multiple planks is scanned and then stored individually after measuring and edge detection. Before the step for the next layer can be repeated, intermediate timbers are stripped with our special traverse.

The Solid Wood Storage SWS combines many years of experience in the field of wood panel handling with innovation in design and software. Our traverse is specially designed for the handling of solid wood and integrates a laser scanner as well as a stripping mechanism.

Your benefits at a glance

- Fully automatic storage of wooden planks on pallets

- Laser scan and photo of the workpieces during store-in

- Automatic wipe-off function for packaging wood

- Edge detection and width measurement during store-in

- Sorting and storage of wooden planks according to their maximum width

- Special suction traverse - ideally suited for solid wood

- Surface preview of the workpiece before store-out or feeding

- Flexible store-in and store-out configurations - also available with roller conveyors

Automatic Laser Scan

of surface and edge contour

A laser scan of the surface not only allows the edge contour to be recognized, but also gives the operator a very good image of the wood grain and surface for the retrieval and feeding process. This makes it possible to determine whether the wood pattern is suitable for further processing or if it is necessary to select a different workpiece to be retrieved.

Fully Automatic Store-in

of delivered planks with wipe-off function for packaging wood

Our Solid Wood Storage SWS enables the fully automatic store-in of wooden planks that arrive stacked on a pallet with packaging wood inbeetween layers. Once the store-in is started, no operator is necessary for until the storage system is ready for the next pallet to load. During the storage process one workpiece after the other is stored and packaging woods are automatically pushed off before manipulation.

Do you need more information or would you like a quote?

Your benefits at a glance

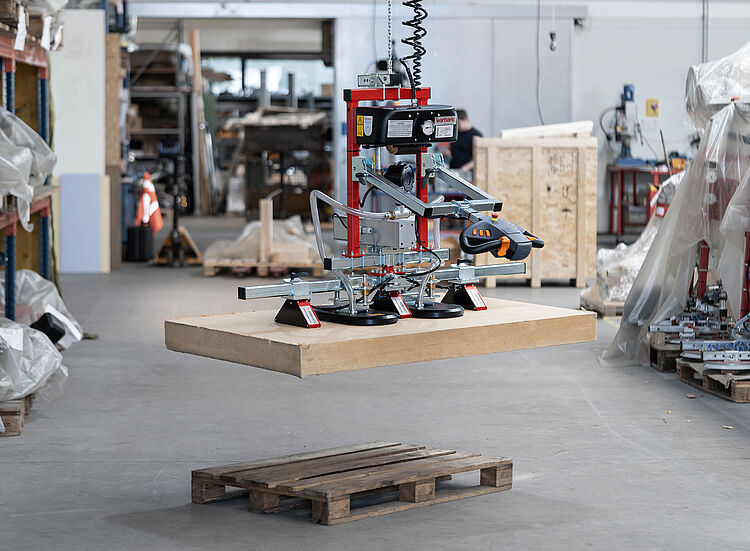

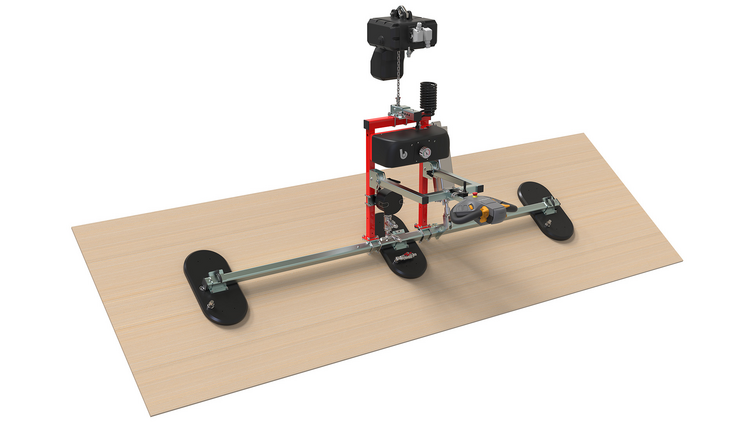

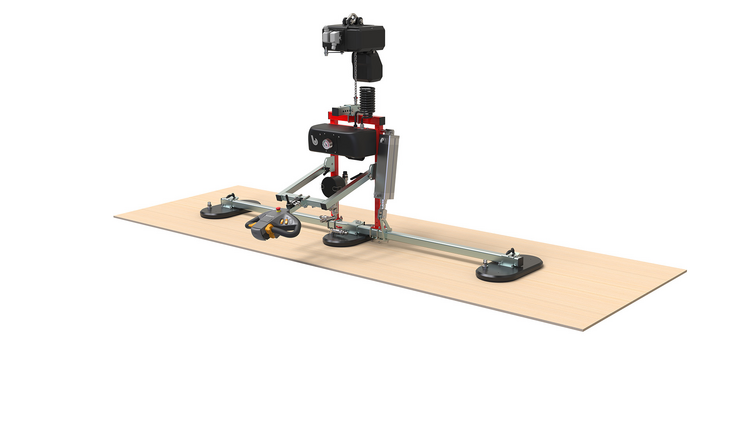

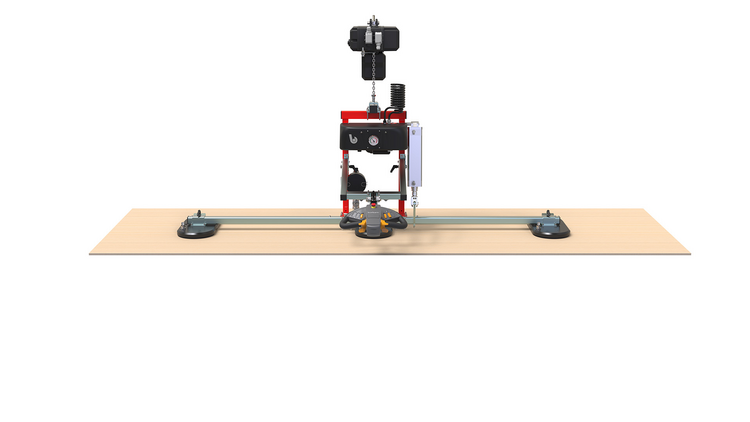

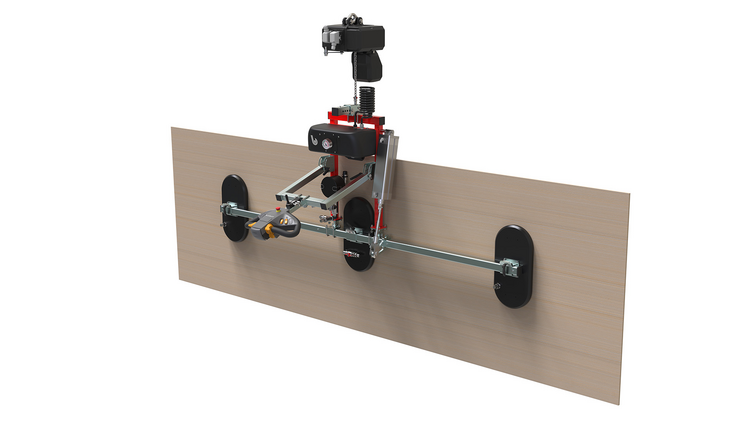

The special lifting device for moving whole posts, solid construction wood, sections such as squadrons or rough sawn boards by a server. Delivery incl. chain hoist or for hooking into an on-site hall crane. Power supply by supply to the customer‘s indoor crane (400 V, 3 phases) due to the built-in transformer possible. Thus, no additional cable is necessary. The control can be carried out via a control handle, wired or by radio.

Technical data

- Load capacity: up to 1500 kg

- Operating voltage: 230 V / 50 Hz or (400 V / 50 Hz via transformer)

- Functions are displayed by means of lamps and pressure gauges

Special solutions, for example: Control via customer crane operation and higher working loads on request.

Technical changes and errors excepted.

Our Austrian sales representative for vacuum lifters Markus Gruszka presents our SWL PlankLifter at Ligna 2023 in Hannover.

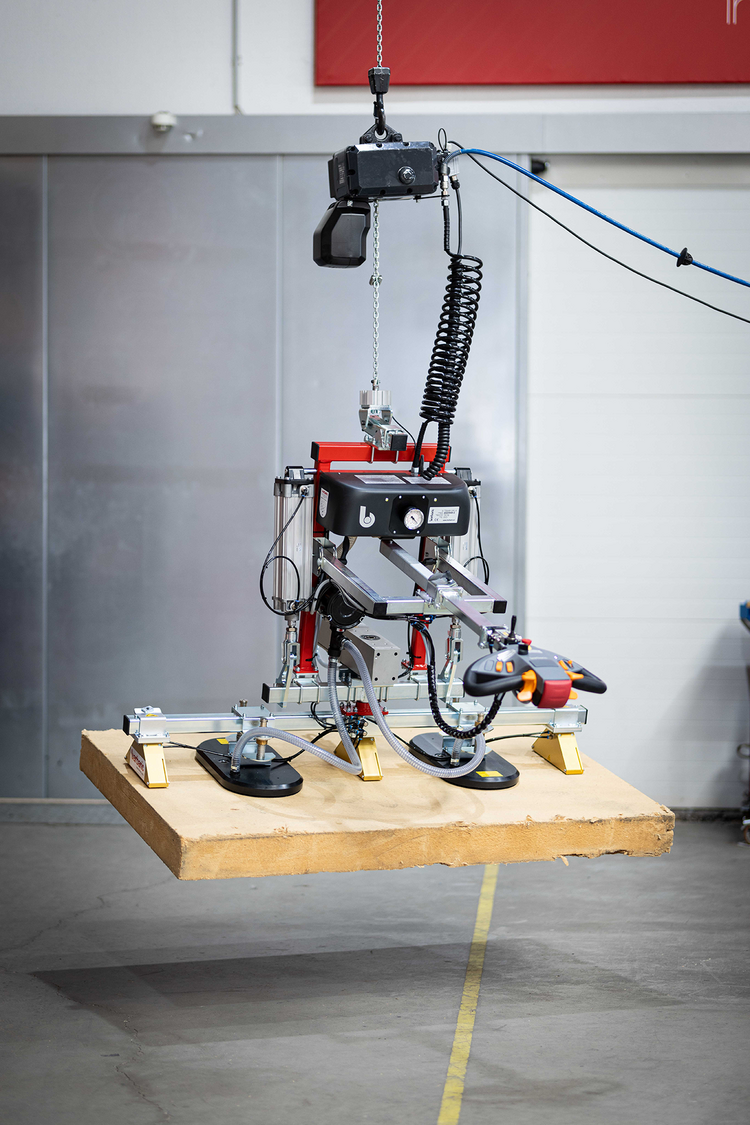

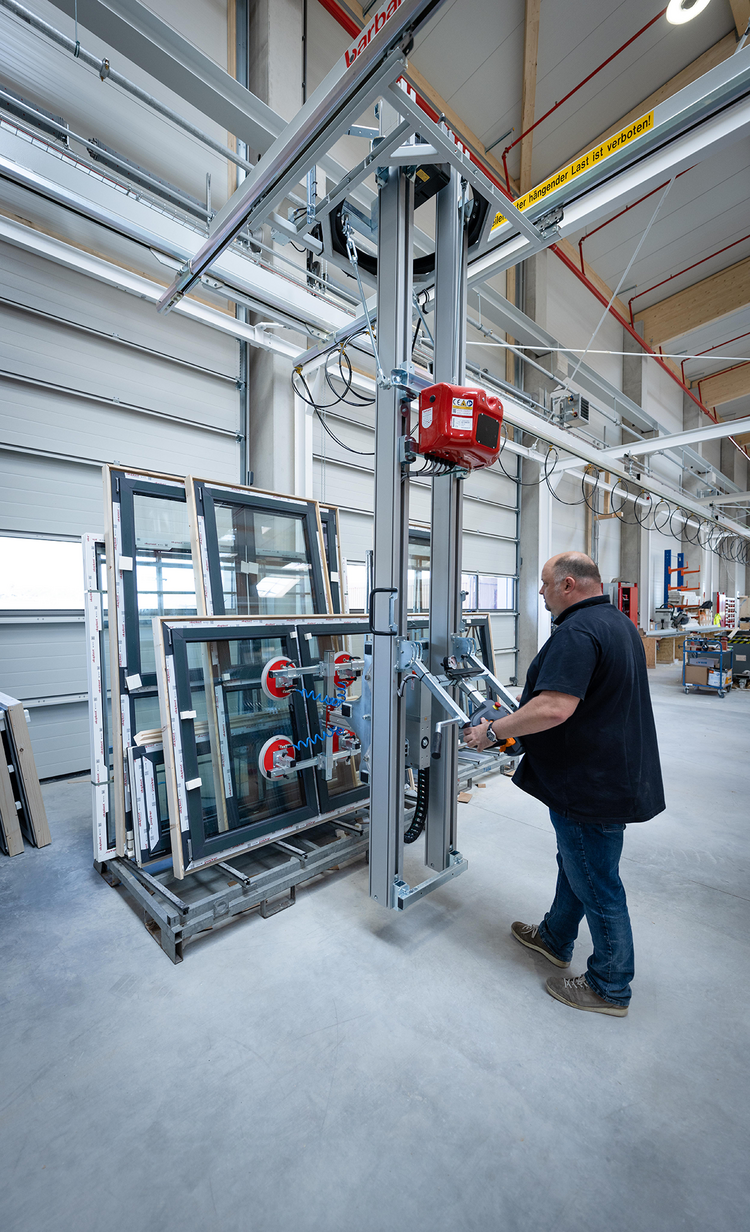

With the RGH Lifter series, we offer lifters with a rigidly guided load arm that enables precise pick-up and set-down as well as effortless and accurate movements under load.

Here you can see our RGH 2 glass lifter in use by one of our German customers (Engelhardt + Geissbauer GmbH), who uses the lifter to install windows and doors in walls for prefabricated houses. Since the delivery of this solution, an operator can effortlessly install windows and doors without further assistance, which at the same time brings a huge increase in productivity and ergonomics.

- Optimal for installing windows, glass or doors.

- Easy and convenient lifting of glass and windows weighing up to 350 kg

- Fast vacuum generation

- Allows effortless movement under load

- Extremely precise placement or installation possible

- Includes optional tilt function (precise movements possible)

- Optional rotation function (up to 360°)

Customer installation at Engelhardt + Geissbauer/Germany

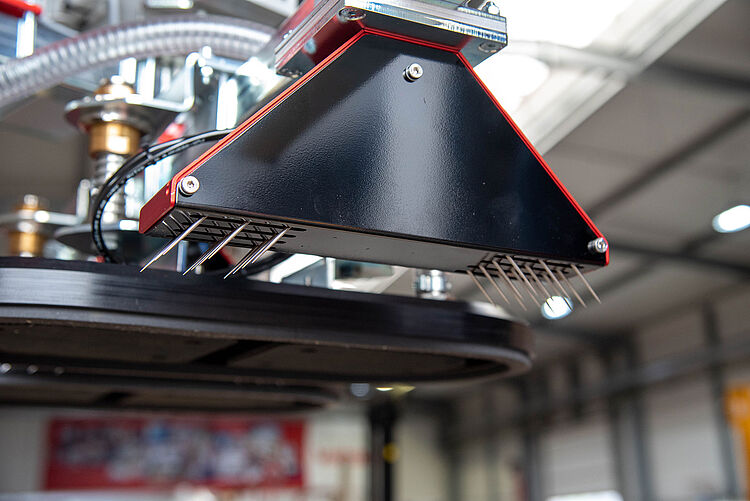

Brand new, innovative and functional.

With our new NeedleGripper, we offer needle gripper lifters for handling wood fiber and other lightweight and insulating materials. Our NeedleGripper NGR are thus ideally suited for all handling applications in the field of prefabricated house construction and the production of insulating materials. Due to the clever design, the lifter can also be used to lift coated panels using our proven suction pads.

Characteristics

- Equipped with needle grippers for wood fiber panels as well as suction cups for regular wood panels

- Effortless handling of wood fiber panels up to 65 kg and regular wood panels up to 100 kg

- Handling controls is integrated in the handle

- Infinitely variable lifting speed control of chain hoist

- Flexible adjustment of suction traverse and handling arm

- Optional 180° Rotation Function

Technical changes and errors excepted.

Quick Demo: Barbaric NGR // Handling of Wood Panels, Drywall and Wood Fiber Panels

Our sales manager René Wisterzil gives a quick demonstration of how the handling of one of our NGR needle gripper lifters works. He shows the lifting of coated particle board as well as a wood fiber panel (lifted through our special needle grippers).

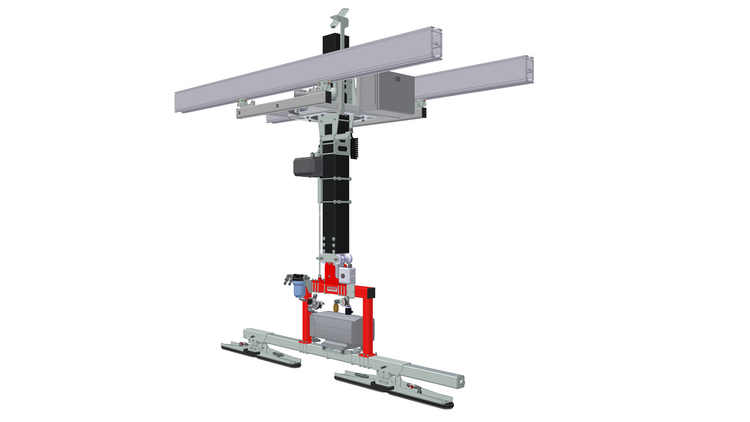

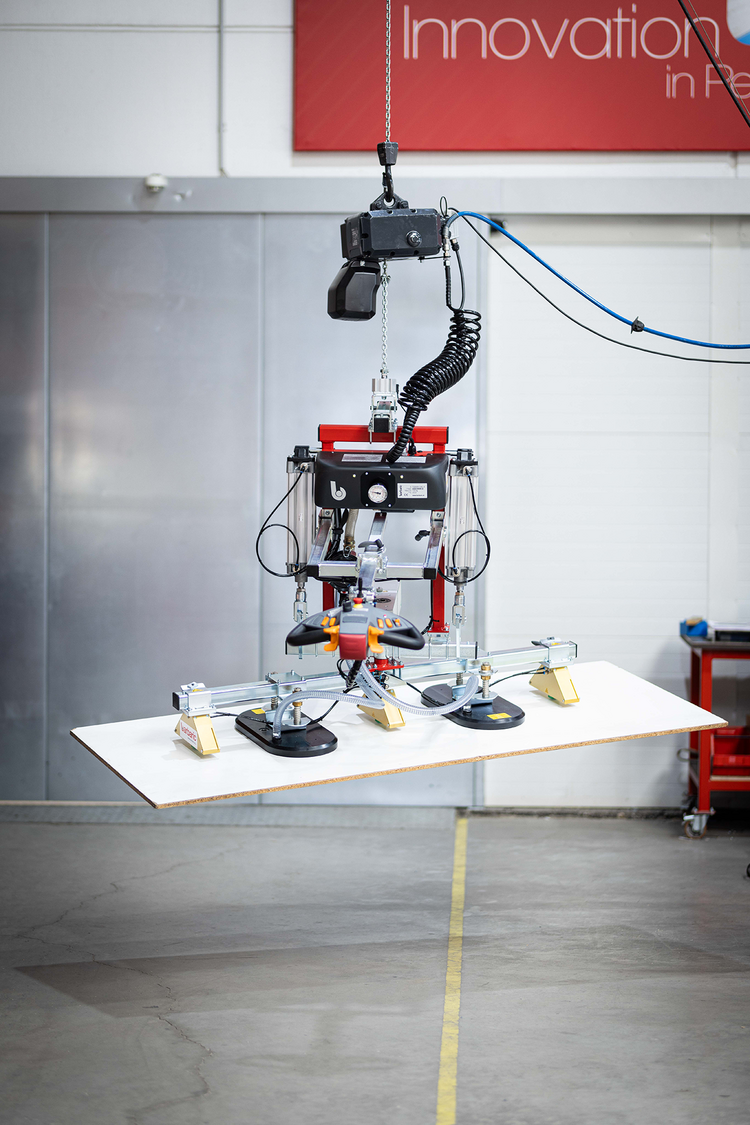

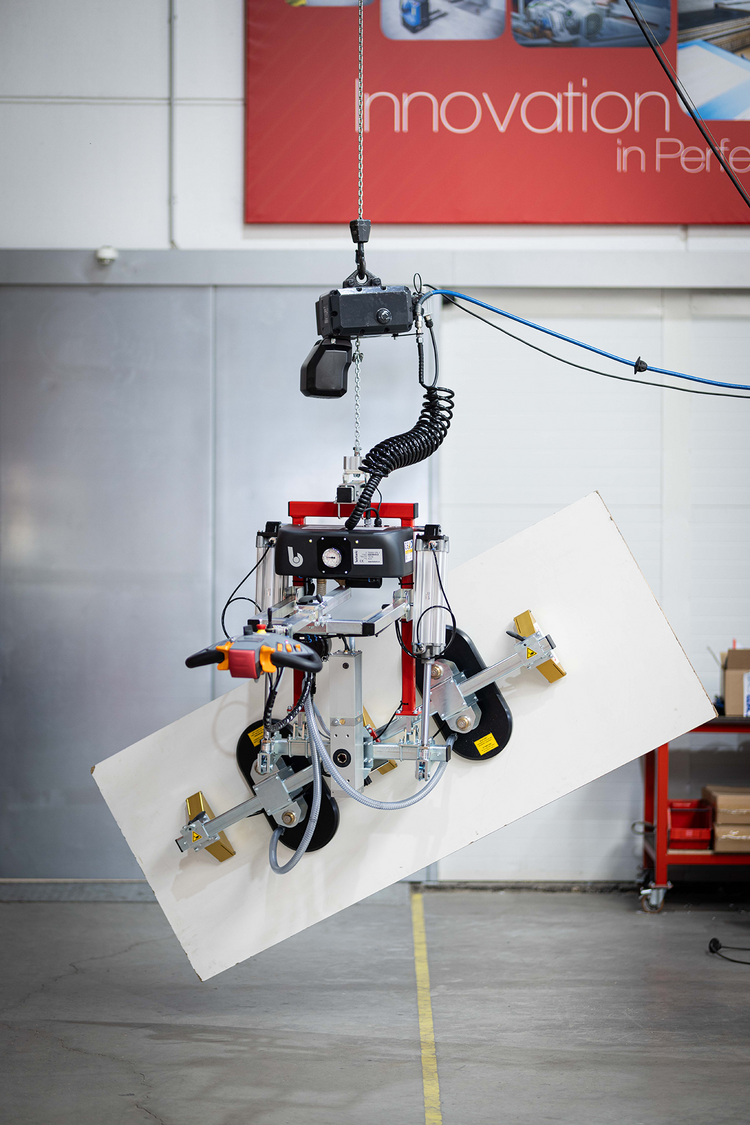

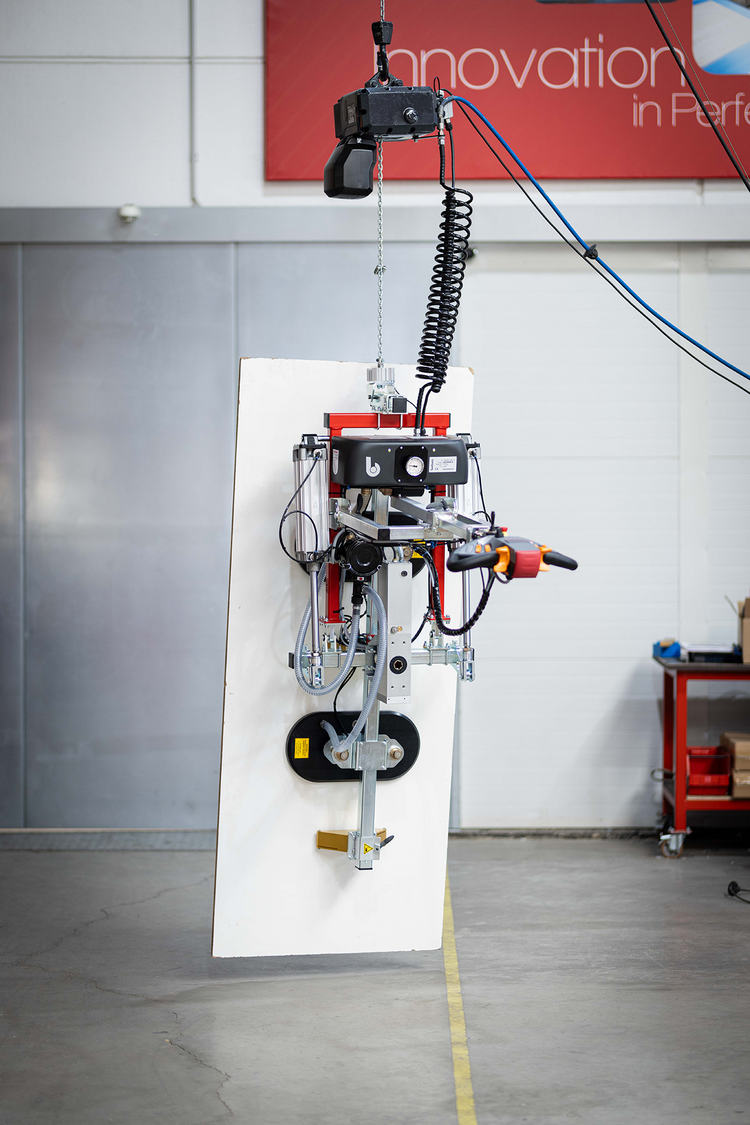

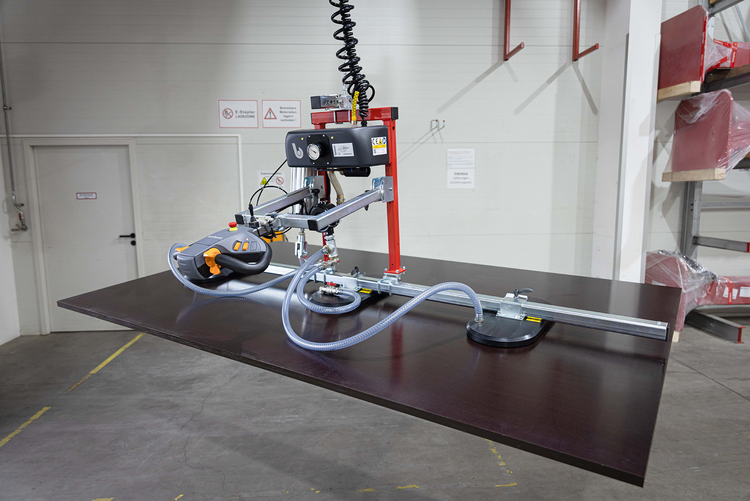

UWL 3J - Large Format Wood Panel Lifter

The UWL 3J is a special version of our bestseller UWL 3, that accommodates even larger panels up to 500 kg. The lifter is equipped with a tilting cylinder for both vertical and horizontal handling of panels. The suction traverse can be individually configured to fit the handling application.

- Specifically built for large format wood panels

- Lifting capacity up to 300 kg and optionally up to 500 kg

- 90° Tilting function for vertical and horizontal handling

- Ergonomic design and easy to use

Functions & Features

- Tilting range of 90°, pneumatically (at version UWL 3J)

- Increased vacuum generation

- Continuously variable liffting and lowering

- Low overall height

- Adjustable operating handle

- Special handle for one-hand operation

Technical changes and errors excepted.

Do you need more information or would you like a quote?

Your benefits at a glance

With its 90 ° tilting function, our UniWood UWL 3 is particularly versatile in the field of wood production, as boards can be manipulated both upright and horizontal. The lifter also impresses with its light, slim design and particularly easy operation. In addition to most commonly used coated wood materialsm, the UniWood UWL 3 is also ideal for handling air-permeable panels (OSB, chipboard, MDF over 8 mm thickness) and materials with a slightly textured surface.

Do you need more information or would you like a quote?

Other features

- Adjustable control handle

- compact design and low build height

- Load capacity: max. 250 kg

- Special operation handle for one-hand operation

- Hoist: continuously, max. 10 m/min.

The perfect combination of Barbaric.

As a complete solution, we also offer our lifters together with the matching craneway system or pillar jib crane as well as various beams with many variations depending on application (details at the end of the page).

Technical changes and errors excepted.

Case studies

Ideas that move!

Learn more about our realized customer projects.

Our sales team is there for you!

If you have any questions or would like a quote, please contact us.

Phone: +43 732 779800

Email: sales-automatic@barbaric.at

After-Sales-Service

We are there for you - even years after the sale.

In order to ensure that our handling systems function optimally, we rely on good cooperation with our customers and particularly customer-oriented support through our competent service team.

Our products

Manual vacuum lifters from Barbaric enable efficient handling of heavy wood and glass panels and save valuable time in production. While conventional manipulation by hand requires 2-3 employees, a vacuum lifting systems allows a single employee to move oversized panels with maximum ergonomics and without physical exertion.

Product overview Manual lifters

Our automatic handling solutions take over fully automated process steps in wood panel and part production. Panel storage and retrieval systems, feeding systems, buffer storage and return systems are just a few examples of modern systems in the field of material handling. All of our machines are built individually according to the requirements of our customers, while proven handling concepts and trusted components are used.