Handling solutions for doors

Optimized production processes, increased productivity and relief of employees. Fast and compact systems in an appealing design for loading a CNC with subsequent stacking of doors.

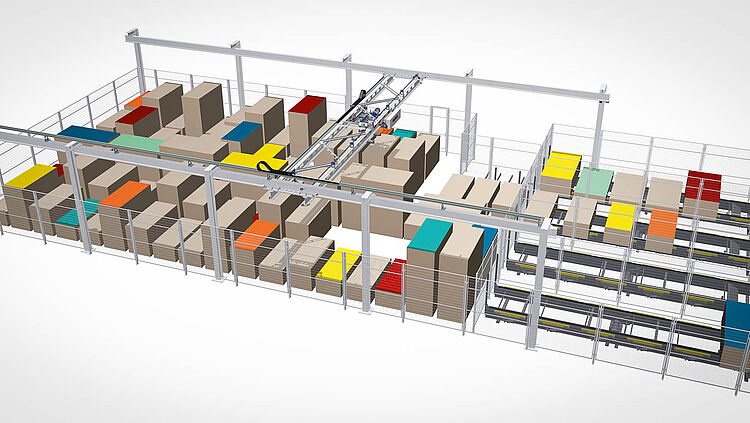

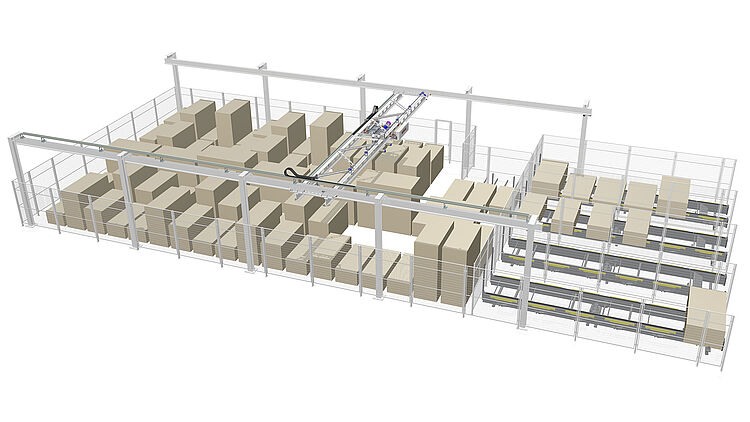

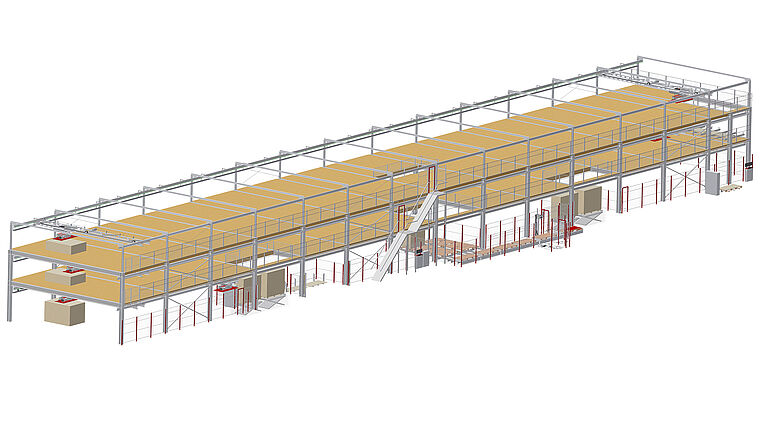

The Barbaric DRX Door Storage System – Fully Automated Storage for Doors, Frames, and Flooring

The Barbaric DRX Door Storage System has been specifically developed for companies in the wood wholesale industry and offers a highly efficient, fully automated solution for storing and picking doors, door frames, flooring, and other packaged goods.

All storage processes are entirely automated: materials are taken directly from incoming pallets and systematically stored. With the use of intelligent barcode systems and optical part recognition, the system ensures simple, fast, and reliable identification of materials. This minimizes errors and significantly increases storage efficiency.

Our integrated software solution provides maximum transparency at all times regarding stock levels and quantities. It also allows seamless integration with customer ERP or logistics systems, ensuring that the DRX Door Storage System fits perfectly into any existing software landscape.

One of the key advantages of the system is its fully automatic picking functionality: at the push of a button, the system compiles complete customer orders. For example, doors are first placed onto a pallet, and then the matching door frames are automatically stacked on top. All this happens without any manual intervention – fully automated, highly reliable, and ready for truck loading immediately after strapping.

The DRX Door Storage System is customized to meet your specific requirements – whether single-level or multi-level. For multi-story setups, pass-throughs in the steel structure or optionally integrated lifting tables allow for smooth and efficient material transport between floors.

A particular highlight of the system is the highly flexible manipulator, which is equipped with both suction cups and a clamping mechanism to handle all materials gently and safely.

Optionally, the system can be expanded with additional manipulators equipped with CSF panel suction traverses, enabling doors, panels, and packaged goods to be stored and managed within a single, perfectly organized storage system.

Choose maximum efficiency, space-saving design, absolute reliability, and tailored solutions – with the Barbaric DRX Door Storage System.

Technical changes and errors excepted.

Features

With the panel storage system CSF Industrial we can offer an individual solution for your special demands. There are no constraints on your wishes. Renowned industrial enterprises count on the stability and reliability of Barbaric systems.

Performance for industrial producers

Our panel storage system CSF Industrial meets the high industrial demands for functionality and performance.

- cycle times below 1 minute

- movement speeds up to 150 m/min

- crane bridge lengths up to 25 m

- integration of chain conveyors or

- conveyor belts

Your benefits at a glance

- extremely large storage areas possible (up to 25 m x 70 m)

- optimized material flow

- gentle manipulation, no damaging of the panels during transport

- optimization of space

- reduced personnel expenses

- simplification and alleviation of production processes

- high transportation services

- highest machine availability

- highest flexibility in production processes

- significant increase in productivity

Technical changes and errors excepted.

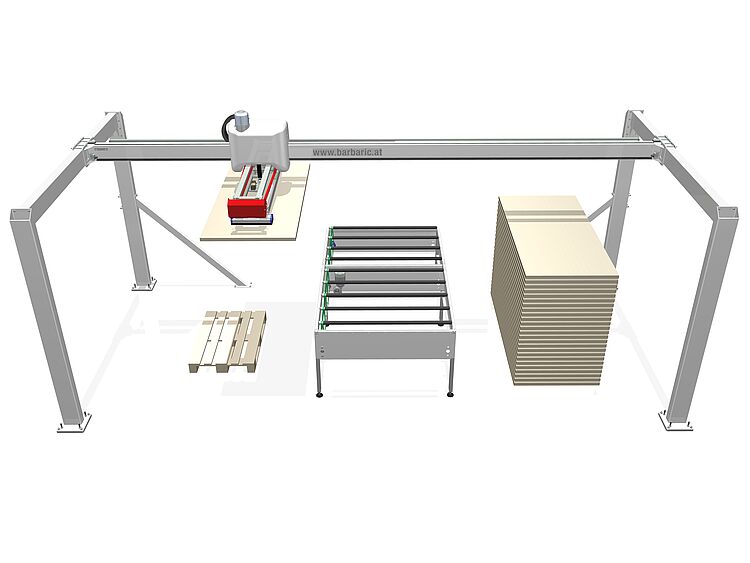

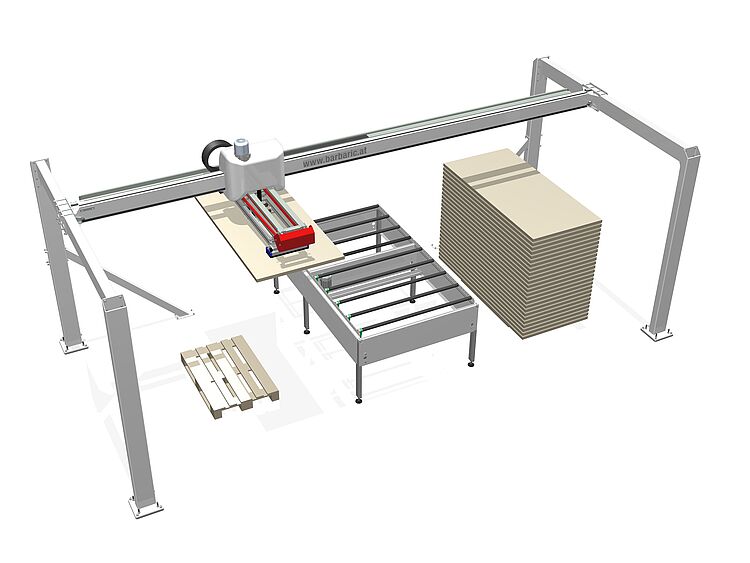

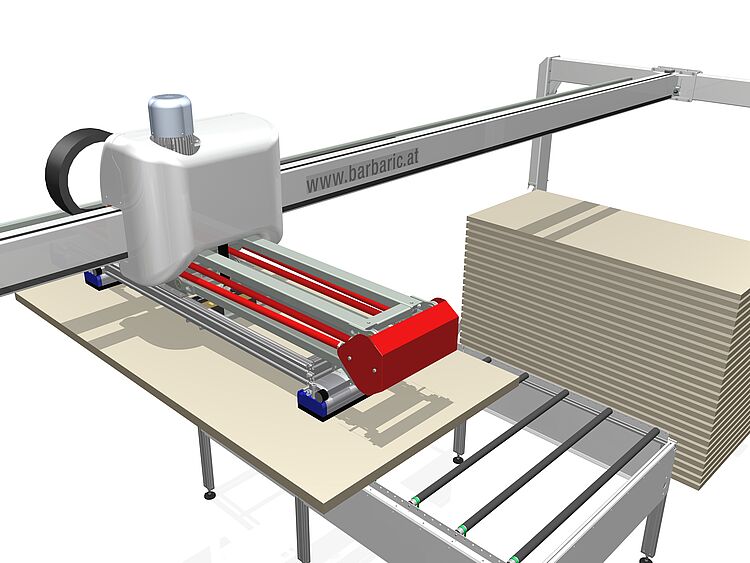

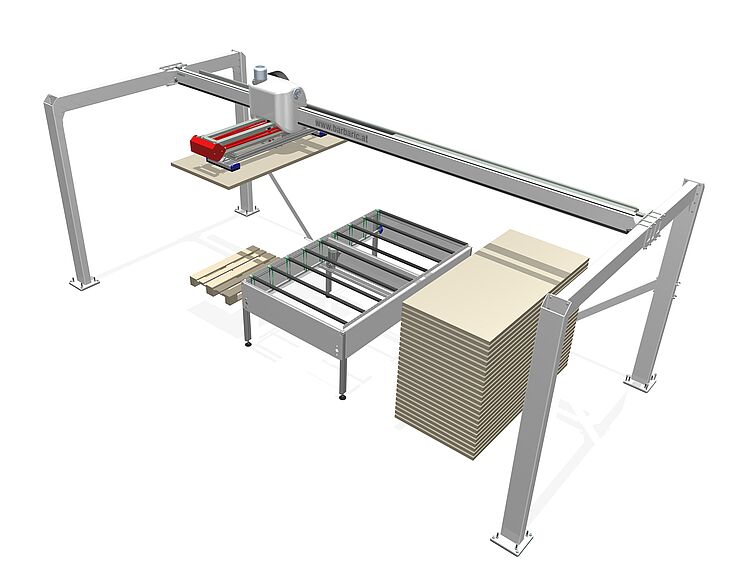

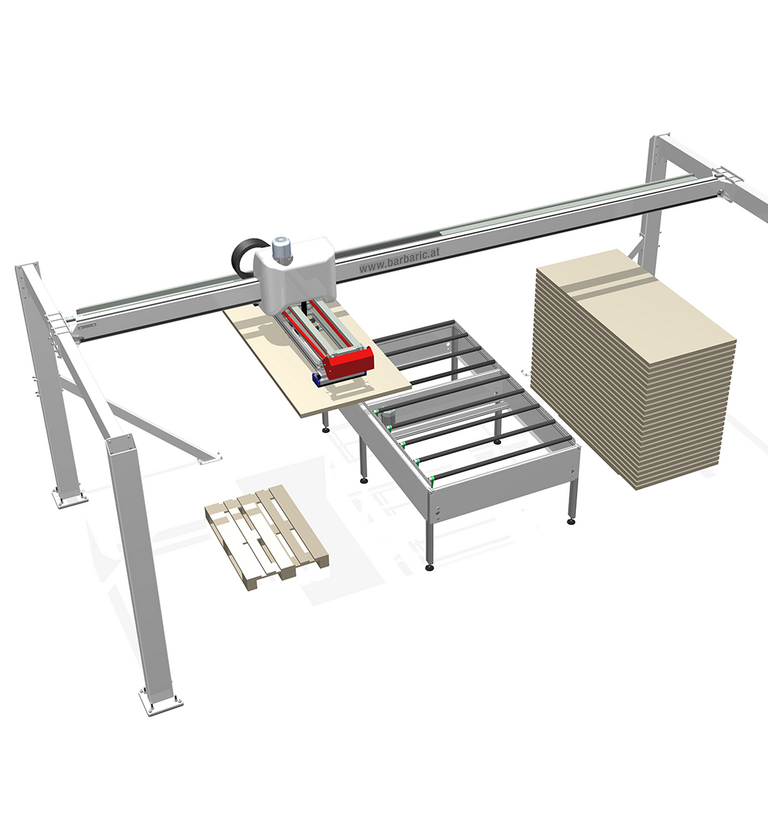

Optimization of production processes in door manufacturing

With the TMP door manipulator, Barbaric is setting new standards in terms of optimized production processes in door manufacturing. The system is characterized by its slim and compact design, which enables very fast manipulation and short cycle times. In addition, roller conveyors or barcode scanning stations can be integrated into the automatic system

Advantages at a glance

The area of application is, for example, the automatic loading of a CNC, subsequent stacking of processed doors or various other stacking processes. The perfect solution for relieving your employees and increasing productivity.

Technical data

- Up to 6 cycles per minute

- Use of surface grippers for structured door surfaces

- Vacuum generation by means of ejectors

- Up to 80 kg load capacity

- Stacking height up to 1800 mm

- Low overall height

Technical changes and errors excepted.

Case studies

Ideas that move!

Learn more about our realized customer projects.

Our sales team is there for you!

If you have any questions or would like a quote, please contact us.

Phone: +43 732 779800

Email: sales-automatic@barbaric.at

After-Sales-Service

We are there for you - even years after the sale.

In order to ensure that our handling systems function optimally, we rely on good cooperation with our customers and particularly customer-oriented support through our competent service team.

Our products

Manual vacuum lifters from Barbaric enable efficient handling of heavy wood and glass panels and save valuable time in production. While conventional manipulation by hand requires 2-3 employees, a vacuum lifting systems allows a single employee to move oversized panels with maximum ergonomics and without physical exertion.

Product overview Manual lifters

Our automatic handling solutions take over fully automated process steps in wood panel and part production. Panel storage and retrieval systems, feeding systems, buffer storage and return systems are just a few examples of modern systems in the field of material handling. All of our machines are built individually according to the requirements of our customers, while proven handling concepts and trusted components are used.