Automation for the timber industry

Automation solutions for solid wood handling, order picking and panel processing.

The innovation for solid wood handling. The Solid Wood Storage SWS combines many years of experience in the field of wood panel handling with innovation in design and software. Our crossbar is specially designed for the handling of solid wood.

The system

The SWS solid wood storage system is the optimal system for the storage of glulam and solid construction wood poles.

Solid wood logs are stored in stanchion compartments and can then be fed to cross-cut saws or joinery lines. Furthermore, there is the possibility of simple commissioning of customer packages or complex package formation after joinery.

These systems impress with their high flexibility. The stanchion compartments can easily be adapted to the desired log widths. Several logs can be stored in one layer per stanchion compartment. This significantly increases the performance of the system compared to conventional one-dimensional storage.

The integration of heavy conveyor technology is essential for this type of plant. Chain conveyors or roller conveyors can be easily integrated into the system.

Do you need more information or would you like a quote?

Simple or multi-level solutions

The solid wood storage system SWS can be realized as a floor storage system but also as a two-storey version.

The standard solution is a warehouse on one level. Depending on the required performance of the system, one or two manipulators can be used.

The next step is a two-level facility. High hall heights are optimally used by adding an intermediate floor to the system and the resulting upper area can also be used for storage.

This area can be used mainly for B&C goods or also for residual bars. The lower stacking heights even allow storage without stanchions.

Software

Connection to customer databases and ERP systems are implemented in the house on the basis of MySQL.

Integration options of

- various databases

- ERP systems

- RFID systems

- CAM systems

- optimization systems

Do you need more information or would you like a quote?

At Barbaric, our goal is to provide optimal solutions for every handling application. In addition to our automatic handling solutions in the field of panel and parts handling for commercial or industrial production lines, we also develop vacuum lifters for all remaining manual lifting processes.

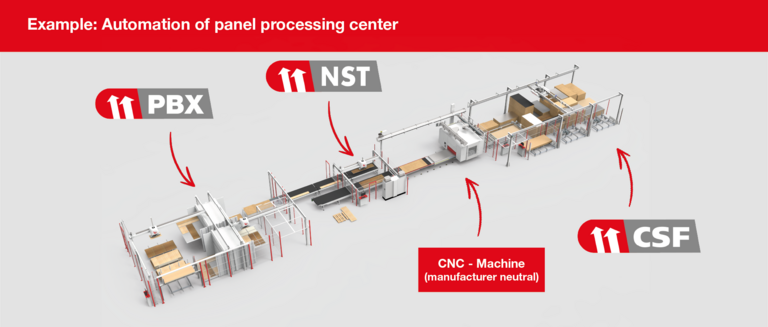

Automatic panel and part handling

Our intelligent solutions are used by many customers around the globe.

- Panel storage systems

- Feeding systems

- Buffer storage

- Return systems

are just a few examples of modern systems in the field of material handling. Each system in this area is built individually according to our customers‘ requirements, while existing components and proven concepts are used.

Do you need more information or would you like a quote?

Manual handling solutions

For customers in the wood and glass industry or for construction site use, we offer the suitable lifting equipment. Barbaric provides optimal handling solutions for safe and ergonomic lifting applications.

Manual vacuum lifters from Barbaric enable efficient handling of heavy panels or glass and save valuable time in production. Heavy lifting tasks can be performed effortlessly by just one operator. By purchasing suitable handling solutions, sickness-related absences can be minimized and attractive jobs can be created for the employees.

Engineering is just as much a part of Barbaric's expertise as standard machinery.

An experienced team of technicians accompanies you from the customer's idea to its design implementation, through production to assembly and handover. The solutions we offer are as diverse as the customer's requirements.

Full-service provider

As a full-service provider, we offer all necessary system components:

- Steel construction

- Mezzanine floors

- Maintenance stairs and ladders

- Mobile gates

- Camera system for system monitoring

Our services – what we offer

- Planning and concept development

- Analysis of customer data

- Simulation using calculation models

- Modern 3D design

- Design reviews with the customer during the project phase

- Regular project meetings

- Assembly and implementation

- Performance tests followed by handover

- Development of service and maintenance plans

Do you have any questions or would you like a quote?

A highlight – load guidance as a double scissor

The double scissor lift design offers many advantages:

- Maximum lift of 4200 mm

- No loss of space when storing panels on the first floor

- Flexibility in space allocation

- Usable room height of up to 3200 mm at floor level

Machine loading

Whether saws or CNCs – almost any processing machine can be placed under the storage system. With a clearance height of up to 3200 mm, operators can work comfortably and industrial trucks also have sufficient space. The steel construction also offers the option of attaching extraction pipes or stationary installations.

Software solutions

The control and networking of machines is particularly valuable in plant engineering.

- Customized programming after creation of a control concept

- Communication between all machines

- Control stations on site and in the control center

- Communication with higher-level production software possible

- Proprietary software for controlling all processes (order management, communication with ERP systems, etc.)

- Backup scenarios

Case studies

Ideas that move!

Learn more about our realized customer projects.

Our sales team is there for you!

If you have any questions or would like a quote, please contact us.

Phone: +43 732 779800

Email: sales-automatic@barbaric.at

After-Sales-Service

We are there for you - even years after the sale.

In order to ensure that our handling systems function optimally, we rely on good cooperation with our customers and particularly customer-oriented support through our competent service team.

Our products

Manual vacuum lifters from Barbaric enable efficient handling of heavy wood and glass panels and save valuable time in production. While conventional manipulation by hand requires 2-3 employees, a vacuum lifting systems allows a single employee to move oversized panels with maximum ergonomics and without physical exertion.

Product overview Manual lifters

Our automatic handling solutions take over fully automated process steps in wood panel and part production. Panel storage and retrieval systems, feeding systems, buffer storage and return systems are just a few examples of modern systems in the field of material handling. All of our machines are built individually according to the requirements of our customers, while proven handling concepts and trusted components are used.